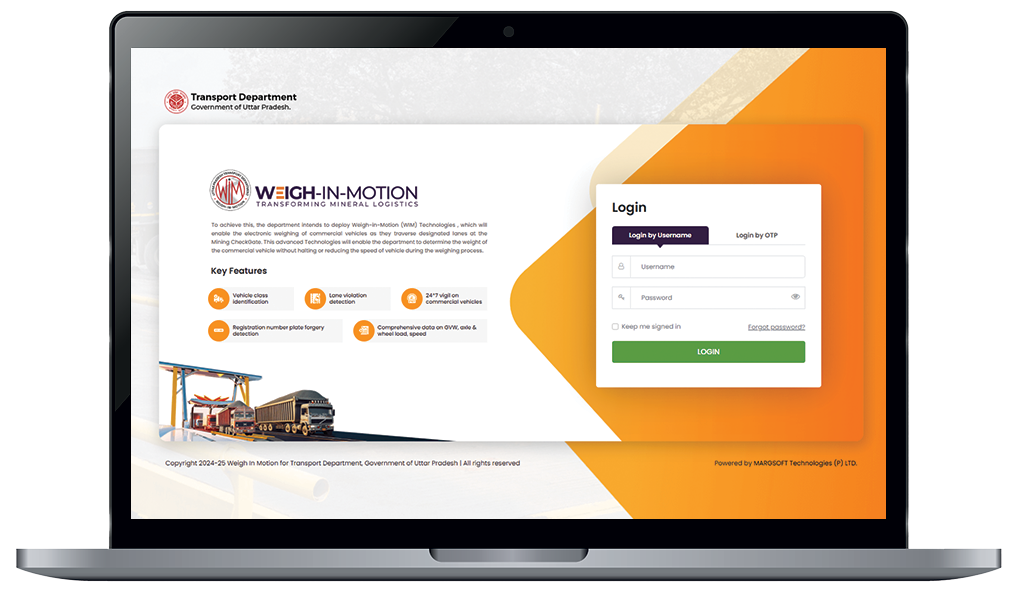

Overview

Establishment of Smart Enforcement System to Monitor Overloading Offences by installing Weigh-In-Motion System and Integration with the existing Mining Checkgate, Established by Directorate of Geology & Mining of the state.

Key Features

Automatic detection and prevention of overloading through Weigh-In-Motion technology, ensuring compliance with legal weight limits.

Curbing pilferage and ensuring fair trade by integrating weigh-in-motion technology with the mining checkgate, leading to increased revenue and fair mineral transportation.

24*7 automated and transparent enforcement through online issuance of e-Notices, speed and lane violation detection to promote legal and safe transportation.

Benefits

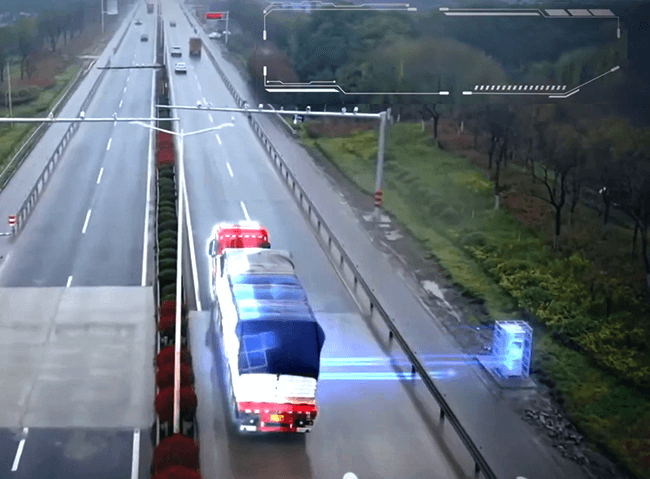

- Automatic real-time overloaded vehicle alert/notification

- Reduction in Road Accidents

- Lane violation detection

- Registration number plate forgery detection

- 24*7 vigil on commercial vehicles

- Online issuance of e-Notices via Mobile & Web portal

- Speed Alert detection

- Increase the lifespan of Road

Weigh-in-Motion System to curb overloading system functions efficiently for vehicles traveling at speeds of up to 80 km/h, capturing all necessary evidence to issue challans to violators.

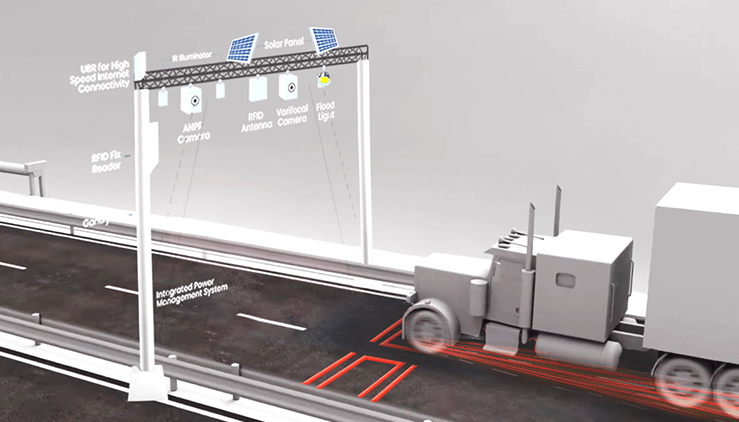

Required Road Conditions for Setup of Weigh-In-Motion (WIM)

Category A

- 'No Lane Violation' Zone Ahead

- Stable tramc (No tramcjam)

- Availability of electrical power

- Network availability for data communication

Category B

- Straight road (visual inspection)

- Without longitudinal slope (visual inspection)

- Small transversal slope (visual inspection)

- Flatness (no ruts, no bulges)

- Quality (no cracks)

- Depth of Road > 90mm

- Road MSA > 60

- Rutting on Road < 2mm

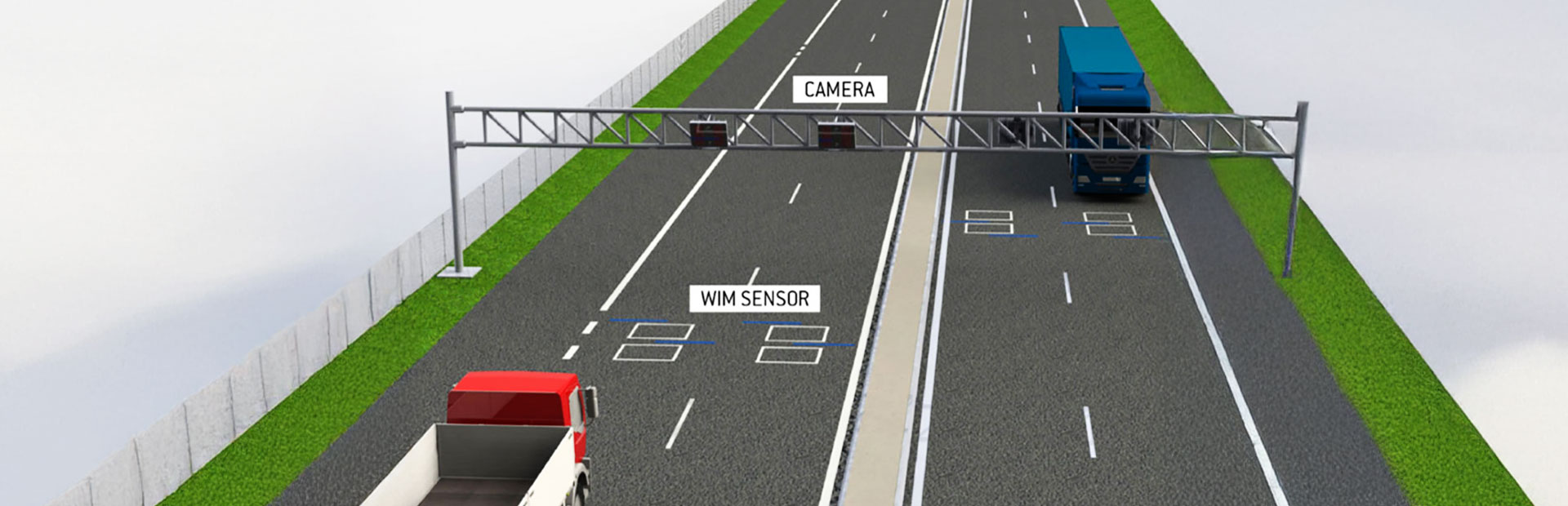

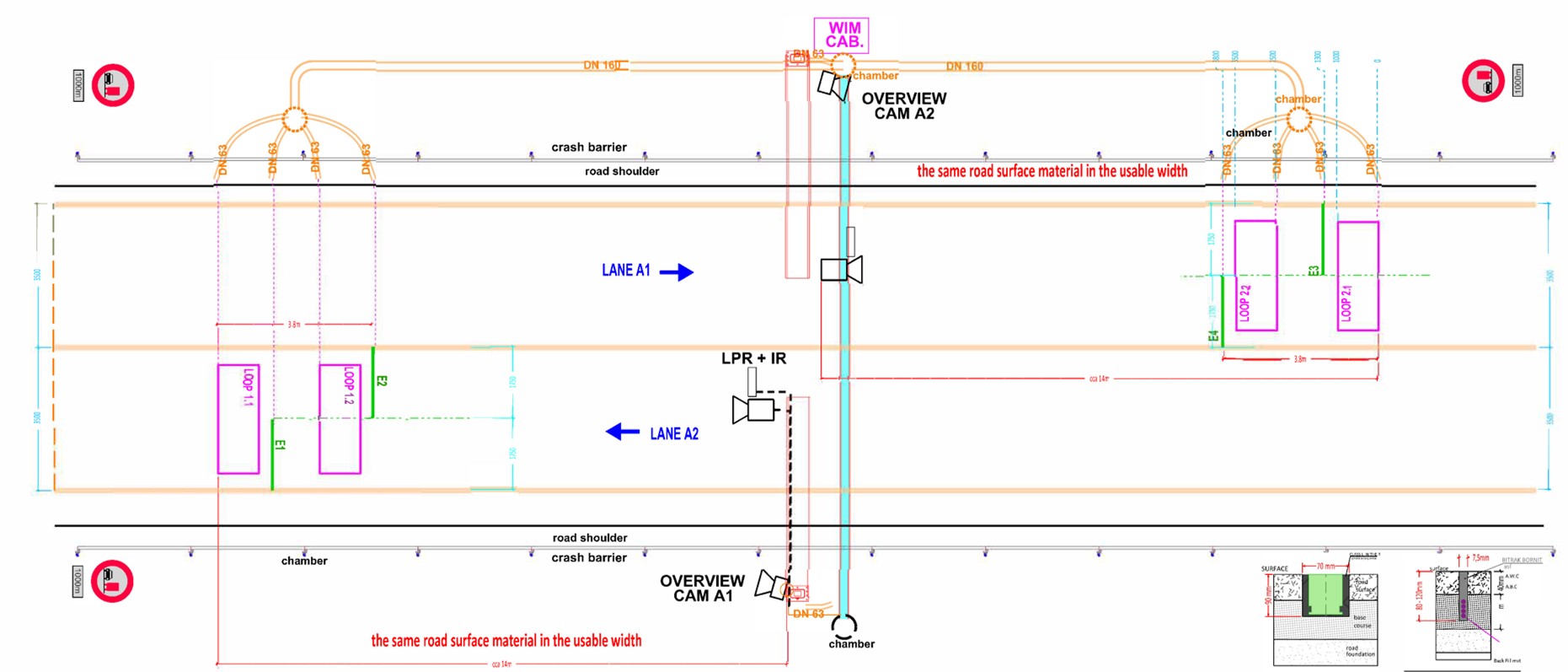

Layout for Setup of WIM

Installation Process

Step 1

Marking on the Road as per Layout

Step 2

Cutting & Cleaning on the Road

Step 3

Grout pouring before placing the sensor

Step 4

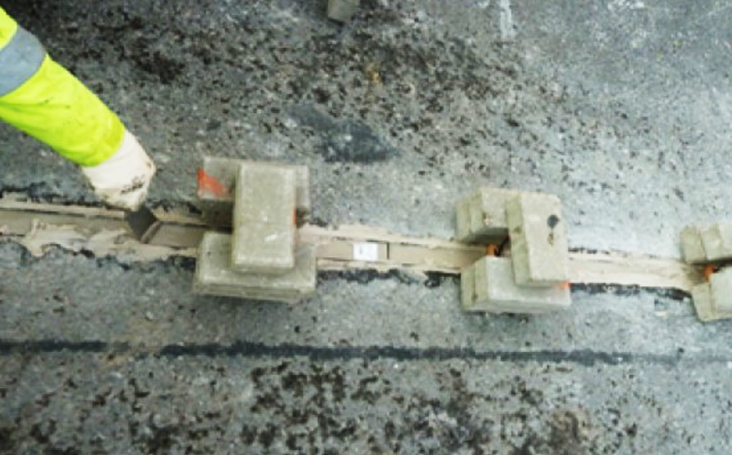

Sensor installation into the road surface

Step 5

Putting Weight on the Sensor until the grout becomes hard

Step 6

Grout hardening